PFA,FEP,F40 spray

Home > PFA,FEP,F40 spray- PFA,FEP,F40 spray

- Category:PFA,FEP,F40 spray

- Consult:13967436663

- Click:189

- Release Date:1970-01-01

- Online Inquiry

Details:

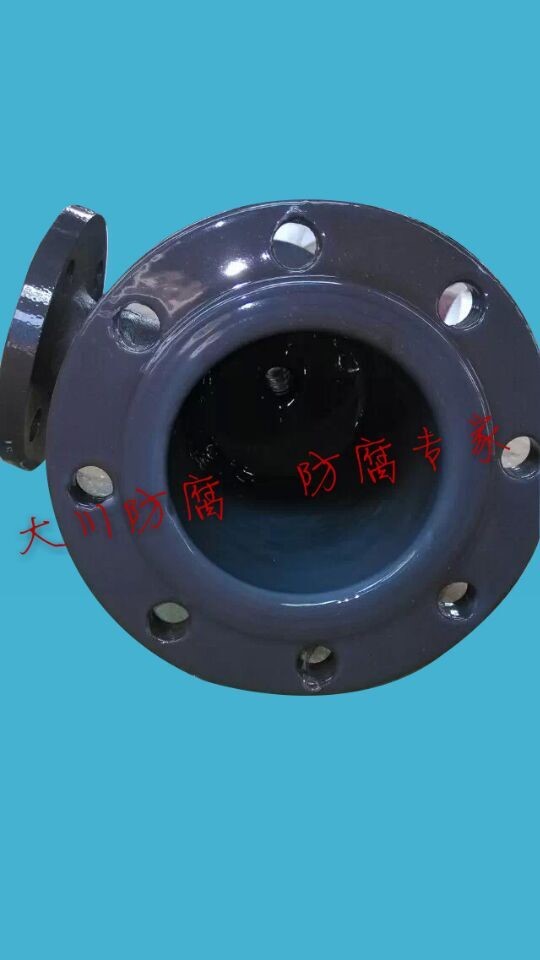

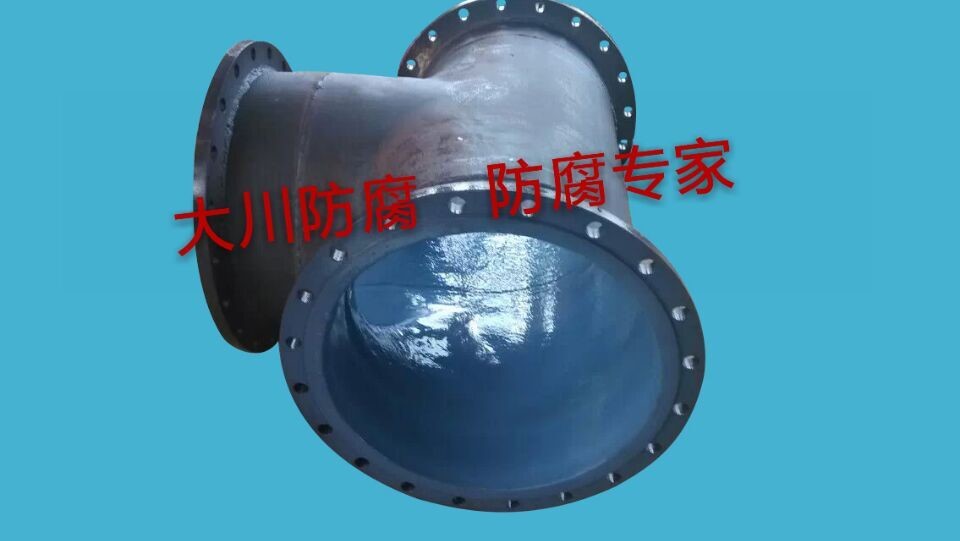

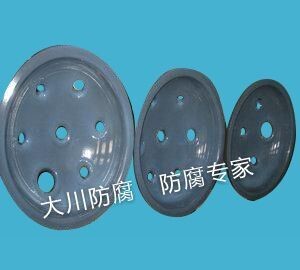

PFA, FEP, F40 spraying

1、 There are several types of equipment structures for PFA, FEP, and F40 spraying:

*External companion tank type storage tank * Jacket heating reactor * Mixing tank * Filter * Non standard equipment * Special requirements equipment

The customer needs to provide the following basic operating condition information:

For example: ① What is the usage temperature? ② What kind of strong acid or strong alkali is reacting in the tank? ③ What are the positive and negative pressures? Structural drawings of 4 tanks? Is there any solid particle wear?

2、 Performance of anti-corrosion materials

PFA, FEP, or F40 spray coating can be selected based on different usage temperatures and mesons:

1. PFA spraying: Chemical composition (copolymer of tetrafluoroethylene and perfluoroalkyl vinyl ether), commonly known as: fusible F4, soluble polytetrafluoroethylene. PFA spraying materials are divided into two brands: DuPont in the United States and Daikin in Japan; Specific gravity 2.15, friction coefficient 0.02, melting point 305, maximum working temperature 260, linear expansion coefficient 13, embrittlement temperature -268, excellent corrosion resistance. Can withstand extreme vacuum.

2. FEP spraying: Chemical composition (copolymer of tetrafluoroethylene and hexafluoropropylene), commonly known as FEP or F46. FEP spraying materials are divided into two brands: DuPont in the United States and Daikin in Japan; Specific gravity 2.15, friction coefficient 0.05, melting point 260, maximum working temperature 200, linear expansion coefficient greater than 8.3, embrittlement temperature -268, excellent corrosion resistance. Can withstand extreme vacuum.

3. F40 spraying: Chemical composition (copolymer of tetrafluoroethylene and ethylene), F40 spraying materials are divided into two brands: DuPont in the United States and Daikin in Japan; Specific gravity 1.74, friction coefficient 0.06, melting point 267, maximum continuous working temperature 150, linear expansion coefficient greater than 13, embrittlement temperature -100, excellent corrosion resistance. Can withstand extreme vacuum.

3、 PFA, FEP, F40 spraying thickness range: generally ranging from 0.3mm to 1.8mm, select thickness within this range according to requirements.

Note: If you need detailed technical details, please contact our company's technical department