Steel lining po PE pipeline equipment

Home > Steel lining po PE pipeline equipment- Steel lined PO.PE pipeline equipment

- Category:Steel lining po PE pipeline equipment

- Consult:13967436663

- Click:140

- Release Date:1970-01-01

- Online Inquiry

Details:

PO is the abbreviation for PLOY polymer in English, with the Chinese name polyolefin. PO resin is a homopolymer of high polymer and ethylene, and polymerizes with olefins such as ethylene, propylene, and butene. It also includes some characteristic blends, reinforcements, and composites. It is a new type of lining material that is corrosion-resistant, anti-static, non-toxic, high-strength, and rigid. Due to the fact that polyolefin (PO) is an olefin copolymer formed by copolymerization of ethylene, propylene, and butene, it not only overcomes the shortcomings of a single component, but also has good toughness and low temperature resistance of polyethylene, high softening temperature of polypropylene, excellent thermal and light stability of polybutene, and maintains the corrosion resistance, impact resistance, and electrical insulation properties of ethylene and propylene. Its usage temperature can be 20-30 degrees higher than polyethylene and polypropylene.

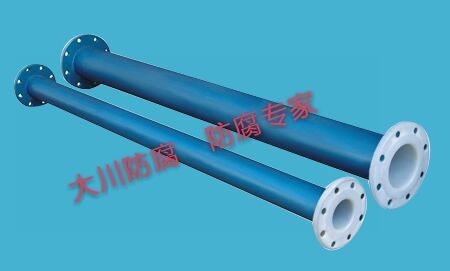

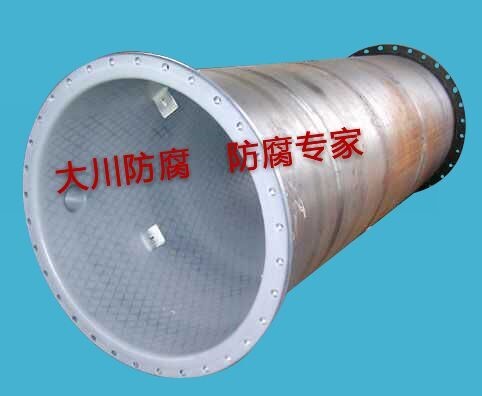

Steel lined PO pipes and fittings are made of carbon steel pipes and lined with high-performance PO materials. Steel lined PO pipes and fittings overcome the disadvantage of poor adhesion between polyethylene and polypropylene and metal, and have strong adhesion. They can firmly bond with metal and are currently one of the ideal choices for anti-corrosion pipelines.

1. According to the manufacturing standard, comply with HG/T2437-93 "Steel Plastic Composite Pipe and Fitting".

2. The flanges of pipelines and fittings are all flat welded flanges, and the flange standard GB/T9119-2000 can also be selected according to the requirements of the purchaser. The flange sealing surface size shall be manufactured and processed according to the sealing surface size specified in the selection standard.

3. 20 # steel pipe shall comply with HG20533 standard; The standard for reducing pipes and tees is HG/T21635.

4. Selection of lining material: PO.

5. The service temperature of steel lined PO pipes and fittings is -30 ℃~100 ℃; The service pressure of steel lined PO pipes and fittings is -0.09Mpa~2.5Mpa (depending on the service temperature and pipe diameter). Steel lined PO pipes and fittings, toughness ≤ 241MPa, tensile strength ≤ 11.7MPa, hardness ≤ 52d

6. It can resist the penetration of small molecule gases, including oxygen, carbon dioxide, chlorine, and hydrogen chloride.

7. High purity, extremely low precipitation rate, meeting the purity requirements of the photovoltaic industry.

8. The surface is extremely smooth and the coefficient of friction is very small. Strong mechanical performance, sturdy, and excellent wear resistance.

Brief description of the steel lining PO rotary forming process:

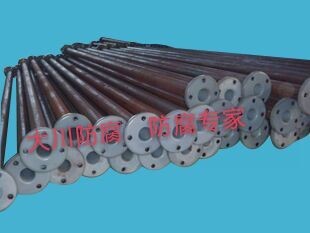

1. Welding and surface treatment of steel pipes and flanges: After welding the steel pipes and flanges, sandblasting to remove rust to Sa2 level, and cleaning impurities, oil stains, etc.

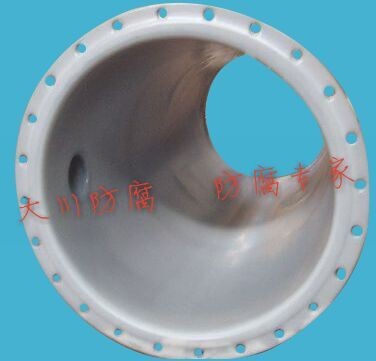

2. Place the pipes and fittings that need to be lined as the lining body in the furnace or on a rolling table, and when heated to a certain temperature, add the powder plastic to the lining workpiece according to the required thickness ratio of the lining area. The powder plastic begins to melt in a semi flowing state, and under the centrifugal force generated by uniform rotation, it uniformly adheres to the lining workpiece. After all the powder plastic melts, continue to rotate until the product cools down and forms a shape.

3. After hydraulic testing at 1.5 times the design pressure for molded lining pipes, pipe fittings, and fittings;

After the water pressure test, 100% integrity inspection and high-frequency electric spark test shall be conducted. The lining product shall undergo high-frequency electric spark 15KW voltage detection, and no leakage or breakdown phenomenon is allowed during the detection.