PTFE storage tank/reaction kettle/negative pressure resistant lining tower section

Home > PTFE storage tank/reaction kettle/negative pressure resistant lining tower section- PTFE storage tank/reaction kettle/negative pressure resistant lining tower section

- Category:PTFE storage tank/reaction kettle/negative pressure resistant lining tower section

- Consult:13967436663

- Click:217

- Release Date:1970-01-01

- Online Inquiry

Details:

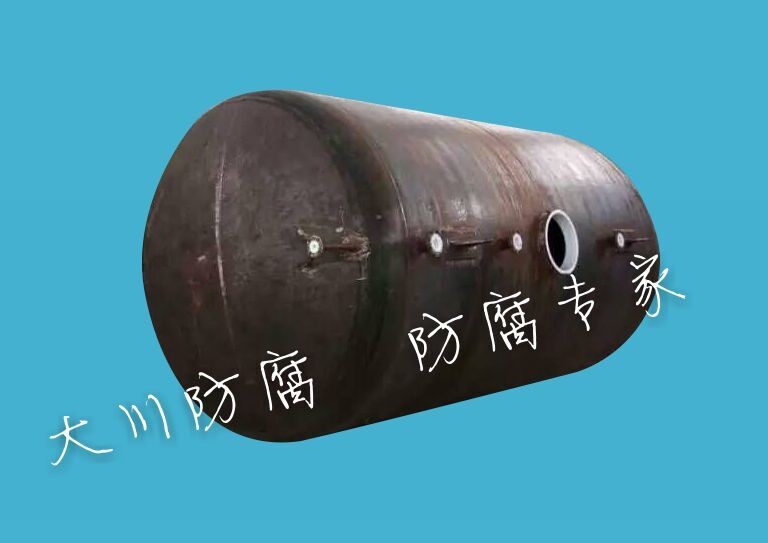

Product Introduction of Lined Tetrafluoroethylene Reactor:

Our company has been committed to the research and development of chemical anti-corrosion for 15 years and has obtained more than ten patents for tetrafluoroethylene anti-corrosion technology and equipment.

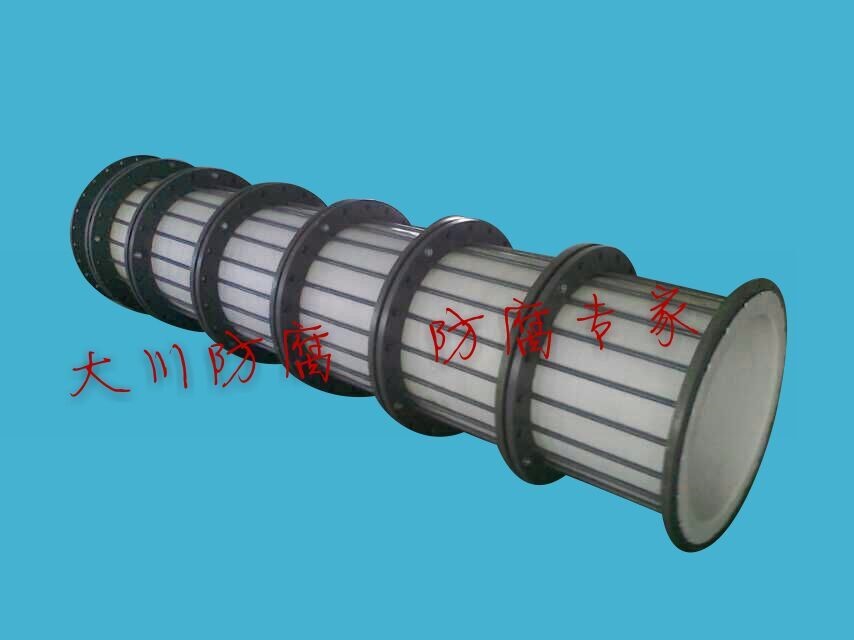

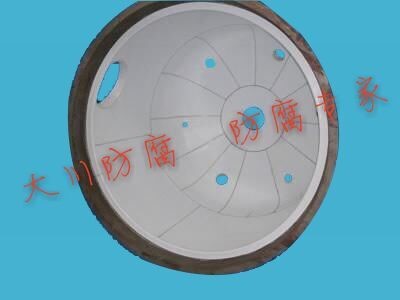

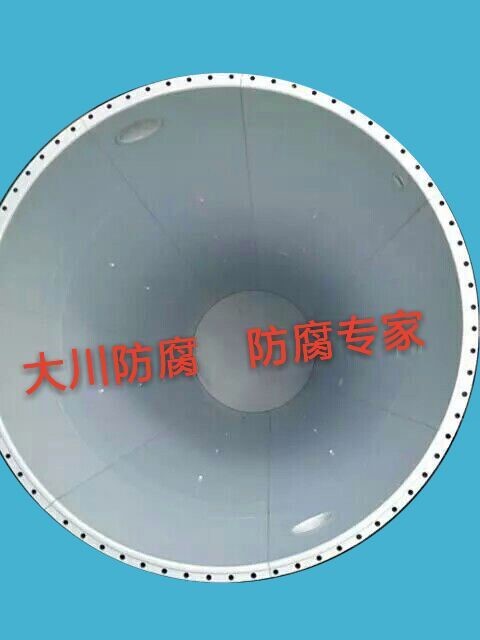

(1) Our factory has three mature processes: plate lining method, negative pressure resistance lining method, and isostatic pressure method for large equipment. We can produce F4 anti-corrosion equipment with inner lining of any specification according to the user's drawing requirements. There is no limit to vertical or horizontal types, and branch pipes can be opened at any position with a length of 150mm;

(2) The thickness of F4 in the inner lining is generally 2-10mm, which can be selected arbitrarily;

(3) Inspection standard: Electric spark flaw detector is used for testing, with a detection voltage of 25kV, a frequency of 1.9 * 106 Hz, and a surface movement speed of probe F4 not exceeding 50mm/sec to avoid breakdown of qualified products.

Scope of application of lined PTFE reaction kettle:

Various strong acids and alkalis, the heating temperature outside the kettle shall not exceed 180 ℃, and the operating temperature inside the kettle shall not exceed 180 ℃. The heating speed should be slow. The temperature outside the kettle can be gradually controlled through a PID temperature control system to gradually control the temperature inside the kettle. Due to the lining of PTFE inside the stainless steel kettle and outside the temperature measurement protection tube, special attention should be paid to the temperature difference between the heating temperature of the heating furnace outside the kettle and the temperature measured inside the kettle by the temperature measurement protection tube. Excessive external temperature can easily cause the melting and deformation of the PTFE inner liner. The reaction kettle with inner lining of tetrafluoroethylene shall not be used for vacuum extraction. After the reaction is completed, the cover can only be opened for material extraction after the temperature decreases and the pressure disappears. It is not allowed to use valve opening to vent and cool down to avoid emptying the tetrafluoroethylene sleeve

Operating pressure: -0.09-+1.6MPa

Usage temperature: -100 to+200

Inner lining thickness 2-5mm

The working principle of the lined PTFE reactor:

Utilizing the superior physical and chemical properties of various PTFE products to achieve ideal anti-corrosion effects.

Product description of lined PTFE reaction kettle:

Teflon Teflon inner lining refers to the uniform lining of polytetrafluoroethylene resin or Teflon Teflon polytetrafluoroethylene plate in metal containers using special processing methods such as hydraulic process, equal pressure forming process, hot pressure welding process, and bonding process. Product varieties and uses: The varieties of Teflon inner lining products include: polytetrafluoroethylene reaction kettle, tank, groove, straight pipe, elbow, tee, cross, compensator, corrugated pipe, etc. Teflon inner lining products are widely used in chemical anti-corrosion fields such as strong acid, strong alkali, high temperature, high pressure, and negative pressure.